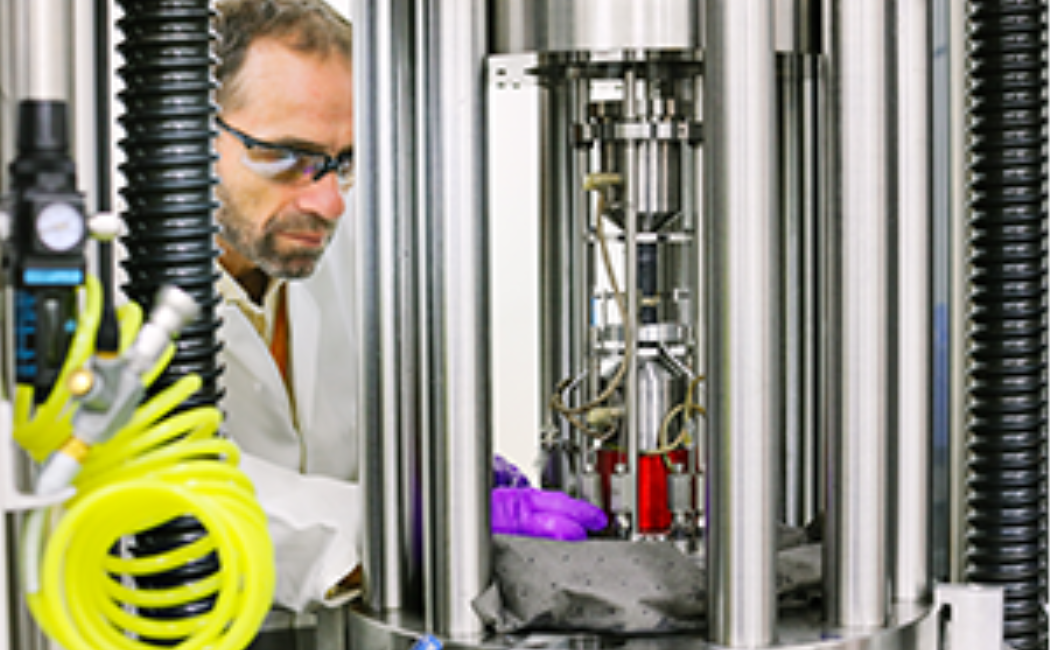

Rock mechanics

Brand: Metarock

Model: 200K Lbs load frame

We operate a triaxial testing system from Metarock designed as a research solution for evaluating mechanical rock properties. The system consists of a single innovative 200k lbs load frame utilizing twin precision aligned ball screws and a high pressure (20,000 psi) and temperature (160degC) triaxial testing vessel. In addition, ultrasonic acoustic measurements and dual pore pressure loops inside of the vessel further enhance the testing and monitoring capabilities. Specifically designed software aids in running fully automated and highly precise test sequences and load cycles with this equipment. Hence, rock specimens up to 1.5" in diameter and 3" in length can be subjected to realistic in situ stress, temperature, and pore pressure conditions down to several km depth. With this, their mechanical behavior during loading and unloading can be monitored and analyzed providing important understanding of rock deformation and quantifying their specific parameters that are critical for describing and forecasting mechanical rock behavior in the reservoir during drilling, production, and injection.